Product

Recommended Products

Phosphorus-containing extreme pressure agent

- Product Introduction

-

Brand

Phosphorus content

(%)Acid value

(mgKOH/g)Viscosity

(40℃,CST)Scope of application

Performance Introduction

ASTM D664

ASTM D445

Total synthesis

Semi-synthetic

Emulsion

Pure oil

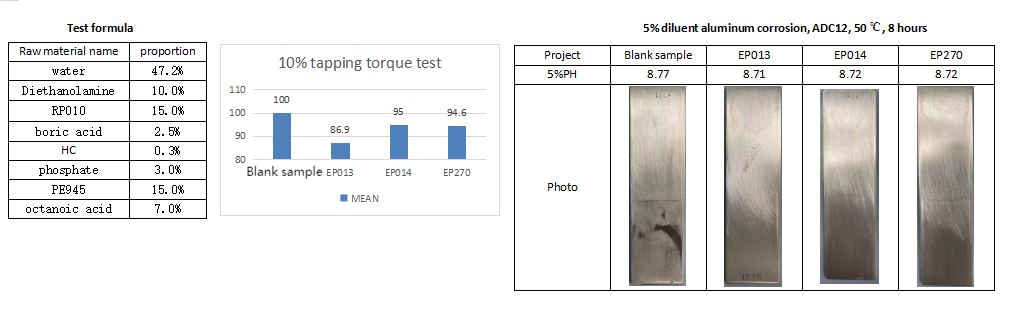

MAXEP 013

2.1

76

111

*

*

*

Water-soluble polyether phosphate, lubricated, extreme pressure, low foaming. MAXEP 014

5.2

187

399

*

*

*

Water-soluble polyether phosphate, excellent lubrication, wear resistance, good hard water stability, compatible with cationic sedimentation agents. MAXEP 270

5.0

200

135

*

*

Water-soluble phenol ether phosphate, lubricated, extreme pressure, low foam, compatible with cationic sedimentation agents. MAXEP 350

-

-

38

*

*

Water-soluble, foam-free, synthetic EP additive used as a heavy-duty lubricant in water-based synthetic metalworking fluids and coolants. MAXEP 360

-

36

200

*

*

*

Water-soluble, foam-free, synthetic EP additives, metalworking fluids are used as heavy-duty and demanding processing environments.

MAXEP series oil-soluble phosphates and their amine salts have excellent extreme pressure anti-wear properties, they can be used in various processing scenarios, and can provide formulators with a variety of addition options and combinations.

Brand

chemical structure

phosphorus content

(%)acid value

(mgKOH/g)Viscosity

(40℃,mm²/s)Application Model

Performance Introduction

ASTM D664

ASTM D445

total synthesis

semi-synthetic

Emulsion

pure oil

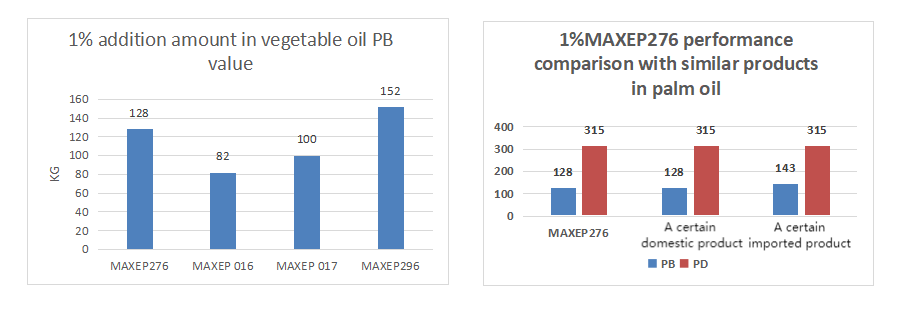

MAXEP 016

phosphoric acidEsterAmine salt

9.9

350

335

*

*

*

Low foaming, lubrication, extreme pressure, aluminum slow, it can be used in metalworking fluids, and can also be used in pure oil products. MAXEP 017

phosphoric acidEsterAmine salt

9.7

160

100 (100°C)

*

*

Oil-soluble phosphate amine salt high extreme pressure high anti-wear, can be used in rolling, cutting, forming processing. MAXEP 276

phosphoric acidEsterAmine salt

10.5

221

559 (100°C)

*

*

Oil-soluble phosphate amine salt high extreme pressure high anti-wear, can be used in rolling, cutting, forming processing. MAXEP 296

phosphoric acidEsterAmine salt

7.5

179

236 (100°C)

*

*

Oil-soluble phosphate amine salt high extreme pressure high anti-wear, can be used in rolling, cutting, forming processing. MAXEP 3740

phosphoric acidEsterAmine salt

9.5

255

-

*

*

It’s an ashless wear-resistant and EP additive. It is used in combination with a sulfur carrier to improve the surface finish of the workpiece and increase the service life of the tool. MAXEP 3770

phosphoric acidEsterAmine salt

2.7

55

-

*

*

Due to the special raw material, it has multifunctional properties and can be used as anti-wear, extreme pressure and anti-corrosion additives. Ideal for formulating lubricant products that require high load carrying capacity (FZG). MAXEP 3780

triphenyl thiophosphate

8.9

<10

-

*

*

An ashless EP/anti-wear additive for physical properties lubricants, recommended for hydraulic oils, greases and lubricants with food contact, synthetic lubricants. MAXEP 232

ashless butyl triphenyl sulfide

phosphate substitute7.9

<10

55

*

*

It can replace phosphate ester ZnDTP, chlorinated paraffin and can increase product lubricity in a good formulation, and it is non-corrosive to copper and iron metals. MAXEP 211

Ashless nonyl triphenyl sulfur

phosphate substitute4.3

<1

3000

*

*

It can replace phosphate ester ZnDTP, chlorinated paraffin and can increase product lubricity in a good formulation, and it is non-corrosive to copper and iron metals. MAXEP 61

ashless dithiophosphate 9.7

<10

5

*

A kind of ashless extreme pressure additive for metalworking fluids, lubricating oils, greases, engine oils, etc. MAXEP 353

dialkyl dithiophosphoric acid

ester derivative9.3

160

90

*

*

Multifunctional properties as EP/AW additives and corrosion inhibitors, easy-to-handle liquids, no diluents. MAXEP 355

ashless dithiophosphate 6.6

120

260

*

*

Extreme pressure good solubility and good application: hydraulic oil, grease, gear oil, metalworking fluid is especially suitable for synthetic refrigeration oil, the amount of 0.01-2.0%, can be used for hydraulic oil, grease, gear oil, metalworking fluid.

keyword:Yucheng

Previous Page

Next Page

Message consultation

Our staff will contact you within 48 hours (working days).