Lubricating MAXEP 017/276 phosphate ester amine salt "has better lubrication, anti-emulsification and low foaming tendency than traditional phosphate ester anti-wear agents"

Release time:

2023-09-13

1. Product Introduction

1. MAXEP series phosphate amine salt has excellent anti-wear and extreme pressure properties;

2. Ash-free products;

3. Good anti-emulsification ability;

4. It has good compatibility with all kinds of base oil;

5. Recommended for stamping stretching, cutting, rolling and other pure oil products, can also be used in metal processing fluid;

6. Recommended addition: 0.5-3.0%

Basic product data

|

Project |

MAXEP 017 |

MAXEP 276 |

|

Phosphorus content (%) |

9.7 |

10.5 |

|

Acid number (mg KOH/g) |

136.0 |

221.0 |

|

Kinematic viscosity at 100 ℃ (mm²/s) |

100.0 |

559.0 |

- Performance Test

Below we will show the performance comparison of phosphoric acid ester amine salt and traditional phosphoric acid ester, Here we use Shanghai Yucheng's N-5 phosphate additives for comparison

1.PB performance comparison

Extreme pressure properties in different base oils

Test method: GB/T3142

Test conditions: 0.5% additive+99.5 0N/T22/Vegetable oil

Summary: MAXEP276 showed excellent extreme pressure performance in all kinds of base oils. MAXEP017 showed excellent extreme performance in 150N, and the lubrication performance showed a downward trend in T22 and vegetable oil.

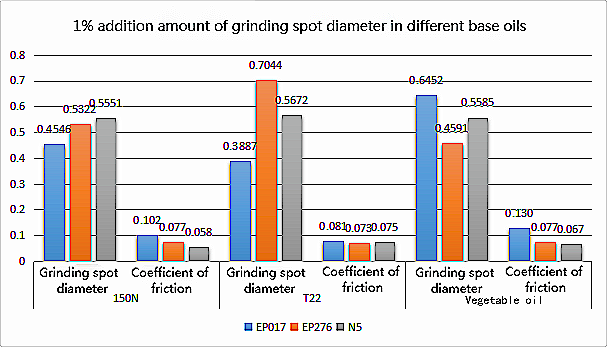

2. Long grinding performance comparison

Test scheme: 1% additive+99 0N/T22/Vegetable oil

Test method:Normal temperature environment, grinding for 60 minutes at 1200rpm/min under a pressure load of 40kgf

150N in the wear spot picture

|

Project |

EP017 |

EP276 |

N5 |

|

Grinding spot diameter |

0.4546 |

0.5322 |

0.5551 |

|

Long grinding picture |

|

|

|

Picture of wear spots in T22

|

Project |

EP017 |

EP276 |

N5 |

|

Grinding spot diameter |

0.3887 |

0.7044 |

0.5672 |

|

Long grinding picture |

|

|

|

Picture of grinding spots in vegetable oil

|

Project |

EP017 |

EP276 |

N5 |

|

Grinding spot diameter |

0.6452 |

0.4591 |

0.5585 |

|

Long grinding picture |

|

|

|

Summary:

MAXEP017 showed lower wear tendency in 150N and T22 base oil;

MAXEP276 showed lower wear tendency in 150N and vegetable oil;

N-5 showed the stability of various types of base oil compatibility.

3. Performance of compounding with sulfur agent in pure oil

Test conditions: 1% additive +1.5% 40% sulfur content sulfurized olefin in 150N

|

|

Blank sample |

EP017 |

EP276 |

N5 |

|

PB |

88 |

121 |

135 |

114 |

|

Wear spot diameter |

0.6762 |

0.4686 |

0.4297 |

0.6043 |

|

Coefficient of friction |

0.081 |

0.079 |

0.059 |

0.071 |

|

Picture |

|

|

|

|

4. Performance of mixed with sulfur agent and chlorinated paraffin in pure oil

Test conditions: 1% additive +1.5 40% sulfur content sulfurized olefin + 6% chlorinated paraffin in 150N

|

|

Blank sample |

EP017 |

EP276 |

N5 |

|

PB |

94 |

121 |

181 |

128 |

|

Wear spot diameter |

0.5368 |

0.4496 |

0.4418 |

0.8377 |

|

Coefficient of friction |

0.081 |

0.074 |

0.057 |

0.081 |

|

Picture |

|

|

|

|

Summary: MAXEP phosphate amine salt has better additive synergy in the formulation.

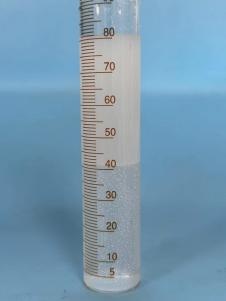

5.Anti-emulsification test

Test method: 1% additive is dissolved in 150N, 40ml of test liquid is added into a measuring barrel, 40ml of deionized water is added, and the anti-emulsification condition is recorded by stirring at 1200rpm for 5min at 54 ℃.

|

Project |

EP017 |

EP276 |

N5 |

|

Photo |

|

|

|

|

Oil-water-emulsion layer (ml) |

40/40/0 |

40/40/0 |

0/0/80 |

|

Separation time |

9min |

1min |

30min without separation |

Summary: MAXEP017/276 has excellent oil-water separation performance in pure oil.

6. Lubricating oil foam test

Test method: GB/T 12579

Test concentration: 1% additive dissolved in T22

|

Project |

EP017 |

EP276 |

N5 |

|

24℃ |

50ml/0 |

20ml/0 |

50ml/0 |

|

94.5 ℃ |

20ml/0 |

20ml/0 |

30ml/0 |

|

24℃ |

50ml/0 |

20ml/0 |

120ml/0 |

Summary: MAXEP017/276 exhibits a lower tendency to bubble.

Product Summary:

Lubricating MAXEP 017/276 phosphate ester amine salt has better lubrication, anti-emulsification and low foaming tendency than traditional phosphate ester anti-wear agents.But more sensitive to base oil and additives,Need a reasonable use of formulators.

Related News