Twenty-one carbon dibasic acid RP1145 "not a traditional dimer acid product"

Release time:

2023-09-13

1. Product Introduction

- Excellent emulsifying performance, can reduce the amount of emulsifier used in the formula;

- Excellent cleaning performance, can effectively improve the cleaning ability of the formula;

- The odorless coupling agent replaces the traditional coupling agent such as neodecanoic acid and octanoic acid;

- Good anti-rust performance, can reduce the amount of anti-rust agent used in the formula;

- Excellent corrosion inhibition ability, reduce non-ferrous metal corrosion, alternative to traditional boride;

- Recommended for semi-synthesis, emulsion, cleaning agents and other formulations.

RP1145 is not a traditional dimer acid product

|

Project |

RP1145 |

Dimer acid |

|

Chemical name |

21 carbon dibasic acid |

Thirty-six carbon dimer acid |

|

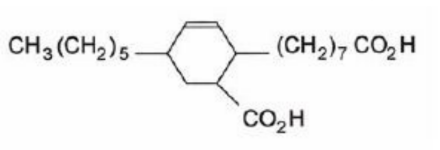

Chemical structure |

|

|

|

Acid number (mg KOH/g) |

260.0 |

190.0 |

|

Kinematic viscosity at 40℃ |

200-300 |

7500-8500 |

|

Performance comparison |

It has the functions of cleaning, lubrication, rust prevention, corrosion inhibition, coupling, and hard water resistance and a large amount of addition will not cause chip sticking. |

Only lubrication and coupling effect, a large number of add will appear sticky chip phenomenon. |

- Performance Test

Test scheme

|

Name of raw material |

Programme 1 |

Programme 2 |

Programme 3 |

|

Water |

62.3% |

62.3% |

62.3% |

|

Triethanolamine |

5.0% |

5.0% |

5.0% |

|

Diethanolamine |

7.0% |

7.0% |

7.0% |

|

AM101 |

3.0% |

3.0% |

3.0% |

|

RP1145 |

3.0% |

- |

- |

|

Dimer acid |

- |

3.0% |

- |

|

Competition |

- |

- |

3.0% |

|

AM02 |

3.0% |

3.0% |

3.0% |

|

Tetra-poly ricinoleic acid ester |

5.0% |

5.0% |

5.0% |

|

MAXLUB 310 |

9.7% |

9.7% |

9.7% |

|

EM07 |

2.0% |

2.0% |

2.0% |

Here we will compare the performance of Shanghai Yucheng Chemical RP1145 according to the above reference formula. The above formula is a transparent and uniform liquid.

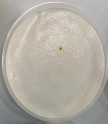

1. Anti-rust performance test

Test method: Dilute the above reference formula scheme 1, scheme 2 and scheme 3 into 5% diluent (Shanghai residents' tap water) and name it as diluent 1, diluent 2 and diluent 3. add 5g cast iron powder into 100ml diluent, soak for 1 minute, take it out and place it on filter paper for 24 hours to observe the rust prevention performance.

|

Project |

Diluent 1 |

Diluent 2 |

Diluent 3 |

|

5%PH |

9.77 |

9.73 |

9.72 |

|

Photo |

|

|

|

Conclusion: RP1145 is consistent with the anti-rust performance of competing products, and the anti-rust performance of traditional dimer acid is the worst.

- Hard water stability test

Test method: Scheme 1, scheme 2 and scheme 3 are respectively diluted with 800PPM hard water containing calcium and magnesium ions according to the proportion of 5%, and named as diluent 1, diluent 2 and diluent 3, and allowed to stand for 24 hours to observe whether there is precipitation and stratification.

800PPM Hard Underwater

|

|

Diluent 1 |

Diluent 2 |

Diluent 3 |

|

Results |

No precipitation |

There's a lot of soap out |

Slight precipitation |

|

Photo |

|

|

|

Conclusion: RP1145 has good resistance to hard water stability.

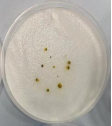

- Corrosion inhibition performance test

Test scheme: Dilute scheme 1, scheme 2 and scheme 3 respectively according to the proportion of 5% diluent (Shanghai residents' domestic water).

Test method: Half of the ADC12 aluminum is immersed in the diluent, the other half is in contact with the air, and the oven is baked at 50°C for 8 hours to observe whether the metal is discolored and black.

ADC12 Aluminum Corrosion

|

Project |

Diluent 1 |

Diluent 2 |

Diluent 3 |

|

5%PH |

9.77 |

9.73 |

9.72 |

|

Results |

Slight corrosion |

Severe corrosion |

Moderate corrosion |

|

Photo |

|

|

|

Conclusion: RP1145 has certain corrosion inhibition performance, which is better than competing products and dimer acid.

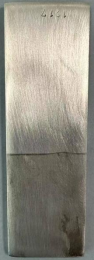

4. Cleaning residue experiment

Test method: Dilute Scheme 1, Scheme 2 and Scheme 3 respectively according to the proportion of 5% diluent (Shanghai residents' domestic water), immerse them in No.10 steel plate for 5min, then take out the steel plate and immerse them in 50-degree, 5% copper sulfate solution for electroplating for 5min to observe the coating condition.

|

Project |

Diluent 1 |

Diluent 2 |

Diluent 3 |

|

Photo |

|

|

|

Conclusion: RP1145 has good cleaning ability, the least residue and the most complete electroplating layer.

Product Summary:

RP1145 is a multifunctional additive that combines rust resistance, corrosion inhibition, coupling, hard water and cleaning resistance.

Related News